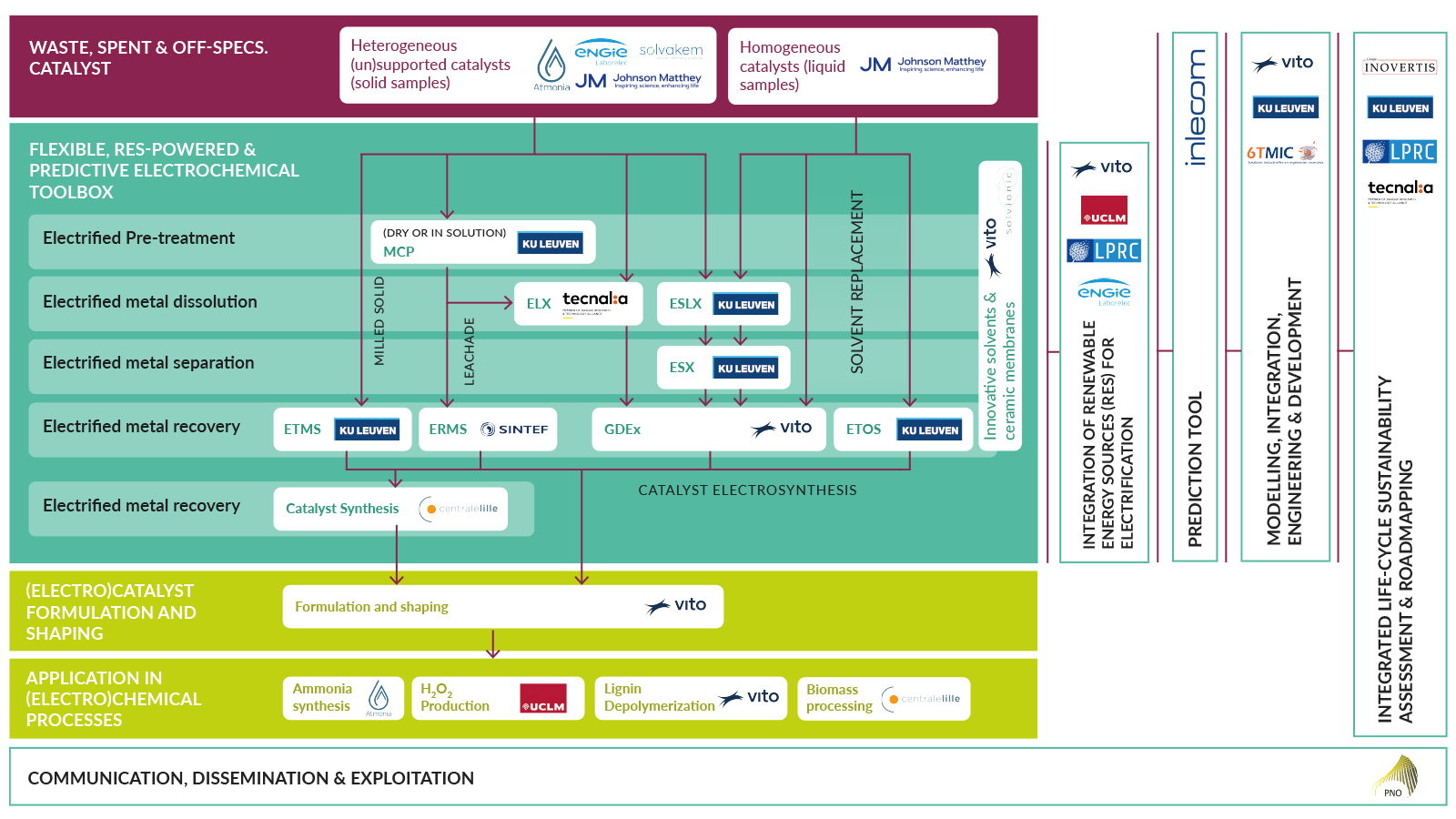

In a revolutionary way, the FIREFLY concept introduces RES in the manufacturing process of (electro)catalysts from secondary resources, which will lower significantly the production costs. Using mainly spent, waste and off-specifications catalysts from different industrial applications, the project follows the road to circularity, proposing more sustainable and viable pathways for the chemical industry.

In a nutshell, the FIREFLY concept focuses on:

- The development of electro-driven technologies for metal recycling from spent, waste, and off-specification catalysts available in Europe – including a modelling, optimization, and engineering approach;

- The efficient integration of renewable electricity;

- The development of a digital tool for predictive decision-making;

- The production of (electro)catalysts for innovative (electro)chemical processes that overcome traditional production associated with high operating conditions, greenhouse gas (GHG) emissions, and lack of circularity.

Three project stages

The technologies involved in the concept will be developed to TRL4, accompanied by an integrated sustainability assessment that will support the selection of the most promising technology routes based on their environmental and techno-economic performance.

The selected flowsheets will form the FIREFLY process, in a small-scale pilot. They will be demonstrated at TRL6 in the predictive, RES powered, and flexible production of new metal-based (electro)catalysts from secondary resources, as well as their application in innovative (electro)chemical processes of selected chemicals:

- Synthesis of ammonia;

- Production of hydrogen peroxide;

- Depolymerisation of lignin;

- Chemical biomass processing.

The activities and results will be effectively communicated, disseminated, and exploited to a wide set of stakeholders.