One of the objectives of the second work package (WP2), lead by La Palma Research Centre (LPRC), is to conduct a Material Flow Analysis (MFA) on the catalyst materials and develop a Geographical Information System (GIS) inventory of catalysts at European level. The primary objective of this work package is to facilitate understanding of catalyst resources for the FIREFLY technology.

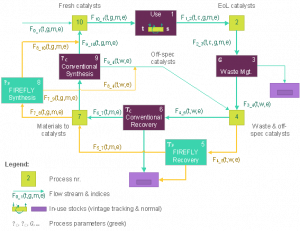

After successfully selecting and characterising catalyst samples from various industrial processes, followed by a thorough analysis of their chemical composition, mineralogy, moisture content and other properties, researchers at LPRC have been studying materials input and output throughout the FIREFLY process, comparing it with conventional recovery and synthesis routes. The analysis relied on complex equations and models, such as the catalyst framework and mass balance equations.

For the past several months, the material flow analysis (MFA) has studied the input and output of materials throughout the FIREFLY process in comparison with conventional recovery and synthesis routes.

The general catalyst framework uses model equations and subsequent computational operations over the course of one year. These operations define values such as outflows, stock changes to ultimately determine the stock of catalyst materials.

Solving the recycling loop

The research team at LPRC placed additional efforts in solving the recycling loop, listing defining equations for various parameters and integrating them into the mass balance equation of the process, which is calculated on a yearly basis.

Geographical Inventory System

By leveraging data compiled with the MFA which contain geographical data, the research team will put together a GIS database. Using the selective catalytic reduction catalysts example, with its coal power plant installed capacity at statistical geographical classification level [nomenclature of territorial units for statistics (NTUS-2)], WP2 is building a comprehensive inventory of catalyst resources across Europe.

Looking ahead, this preliminary database will be handed over to INLECOM, leader of WP5, enabling access to GIS data through a user-friendly interface, making catalyst resource mapping accessible for all stakeholders involved.

| NUTS 2 | NUTS name | Country | Capacity (MW) |

NUTS 2 | NUTS name | Country | Capacity (MW) |

| AT12 | Niederösterreich | Austria | 392 | DE11 | Stuttgart | Germany | 1 686 |

| AT22 | Steiermark | Austria | 220 | DE12 | Karlsruhe | Germany | 1 462 |

| AT31 | Oberösterreich | Austria | 150 | DE21 | Oberbayern | Germany | 805 |

| BG32 | Severen tsentralen | Bulgaria | 290 | DE30 | Berlin | Germany | 998 |

| BG33 | Severoiztochen | Bulgaria | 152 | DE40 | Brandenburg | Germany | 4 600 |

| BG34 | Yugoiztochen | Bulgaria | 271 | DE50 | Bremen | Germany | 805 |

| BG41 | Yugozapaden | Bulgaria | 816 | DE60 | Hamburg | Germany | 1 910 |

| BG42 | Yuzhen tsentralen | Bulgaria | 120 | DE71 | Darmstadt | Germany | 510 |

| HR03 | Jadranska Hrvatska | Croatia | 335 | DE80 | Mecklenburg- Vorpommern |

Germany | 514 |

| CZ02 | Střední Čechy | Czech Republic | 1 248 | DE91 | Braunschweig | Germany | 520 |

| CZ03 | Jihozápad | Czech Republic | 111 | DE92 | Hannover | Germany | 300 |

| CZ04 | Severozápad | Czech Republic | 3 518 | DE94 | Weser-Ems | Germany | 1 570 |

| CZ05 | Severovýchod | Czech Republic | 1 040 | DEA1 | Düsseldorf | Germany | 8 374 |

| CZ08 | Morayskoslezsko | Czech Republic | 800 | DEA2 | Köln | Germany | 5 435 |

| DK01 | Hovedstaden | Denmark | 343 | DEA3 | Münster | Germany | 1 532 |

| DK02 | Sjælland | Denmark | 827 | DEA4 | Detmold | Germany | 875 |

| DK03 | Syddanmark | Denmark | 860 | DEA5 | Arnsberg | Germany | 610 |

| DK04 | Midtjylland | Denmark | 375 | DECO | Saarland | Germany | 2 216 |

| DK05 | Nordjylland | Denmark | 740 | DED2 | Dresden | Germany | 582 |

| FI19 | Länsi-Suomi | Finland | 1 043 | DED5 | Leipzig | Germany | 1 866 |

| FI1B | Helsinki-Uusimaa | Finland | 463 | DEEO | Sachsen-Anhalt | Germany | 960 |

| FI1C | Etelä-Suomi | Finland | 388 | DEFO | Schleswig-Holstein | Germany | 290 |

| FR23 | Haute-Normandie | France | 600 | EL53 | Dytiki Makedonia | Greece | 3 401 |

| FR41 | Lorraine | France | 595 | EL65 | Peloponnisos | Greece | 511 |

| FR51 | Pays de la Loire | France | 1 160 | HU21 | Közép-Dunántúl | Hungary | 294 |

| FR82 | Provence-Alpes-Côte d’Azur | France | 600 | HU31 | Észak-Magyarország | Hungary | 836 |

| IE02 | Southern and Eastern | Ireland | 915 | PT16 | Centro | Portugal | 628 |

| ITC3 | Liguria | Italy | 136 | PT18 | Alentejo | Portugal | 1250 |

| ITC4 | Lombardia | Italy | 139 | RO11 | Nord-Vest | Romania | 145 |

| ITF4 | Puglia | Italy | 3 280 | RO21 | Nord-Est | Romania | 200 |

| ITG2 | Sardegna | Italy | 1 230 | RO31 | Sud Muntenia | Romania | 150 |

| ITH3 | Veneto | Italy | 805 | RO41 | Sud-Vest Oltenia | Romania | 4505 |

| ITH4 | Friuli-Venezia Giulia | Italy | 336 | RO42 | Vest | Romania | 1308 |

| ITI2 | Umbria | Italy | 130 | SK02 | Západné Slovensko | Slovakia | 266 |

| ITI4 | Lazio | Italy | 980 | SK04 | Východné Slovensko | Slovakia | 220 |

| NL11 | Groningen | Netherlands | 600 | SI03 | Vzhodna Slovenija | Slovenia | 1 420 |

| NL32 | Noord-Holland | Netherlands | 680 | ES11 | Galicia | Spain | 1960 |

| NL33 | Zuid-Holland | Netherlands | 2 871 | ES12 | Principado de Asturias | Spain | 2123 |

| NL41 | Noord-Brabant | Netherlands | 643 | ES24 | Aragón | Spain | 1 055 |

| PL11 | Łódzkie | Poland | 4960 | ES41 | Castilla y León | Spain | 2 594 |

| PL12 | Mazowieckie | Poland | 3 954 | ES42 | Castilla-La Mancha | Spain | 296 |

| PL21 | Małopolskie | Poland | 1 214 | ES61 | Andalucía | Spain | 990 |

| PL22 | Śląskie | Poland | 5 690 | SE11 | Stockholm | Sweden | 114 |

| PL33 | Świętokrzyskie | Poland | 1 575 | UKC2 | Northumberland and Tyne and Wear |

United Kingdom | 420 |

| PL34 | Podlaskie | Poland | 157 | UKD6 | Cheshire | United Kingdom | 2 000 |

| PL41 | Wielkopolskie | Poland | 2 255 | UKE2 | North Yorkshire | United Kingdom | 480 |

| PL42 | Zachodniopomorskie | Poland | 1 424 | UKE4 | West Yorkshire | United Kingdom | 500 |

| PL51 | Dolnośląskie | Poland | 1 599 | UKF1 | Derbyshire and Nottinghamshire |

United Kingdom | 924 |

| PL52 | Opolskie | Poland | 710 | UKG2 | Shropshire and Staffordshire |

United Kingdom | 1 000 |

| PL61 | Kujawsko-pomorskie | Poland | 283 | UKL2 | East Wales | United Kingdom | 500 |

| PL63 | Pomorskie | Poland | 322 | UKM2 | Eastern Scotland | United Kingdom | 2400 |

| UKNO | Northern Ireland | United Kingdom | 520 |

For background information on the activities of WP2, access the following article.